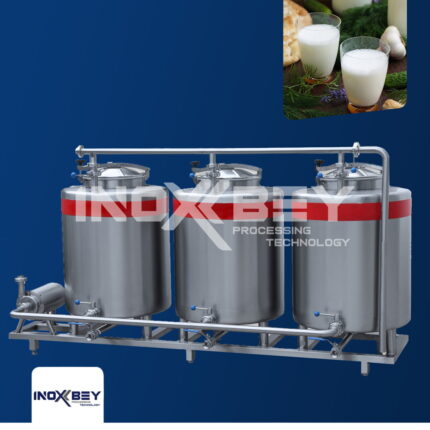

Centrifugal Cream Separators serves to make cream and skim milk, to obtain some cream from whey or sweet-cream buttermilk, and to standardize milk and milk products to a desired fat content. It is applied in the industrial manufacture of nearly all dairy products.

The purpose of this step is to separate milk into cream and skim milk. All incoming raw milk is passed hrough separators, which are essentially high-speed entrifuges. They separate milk into lighter cream fraction and heavier skim milk fraction. A separator of adequate bowl capacity should collect all the slime material containing heavy casein particles, leukocytes, larger bacteria, body cells from cow’s udder, dust and dirt particles, and hair. If the particulate fraction of raw milk is not removed, homogenized milk will develop sediment upon storage. Skim milk and cream are stored separately for further processing.

Use of a separator also permits fractionation of whole milk into standardized milk (or skim milk, low-fat milk) and cream. Skim milk should normally contain 0.01% fat or less. Standardization valve on the separator permits the operator to get separated milk of predetermined fat content. Increased back pressure on cream discharge port will increase fat content in standardized milk.By blending cream and skim milk fractions, various fluid milk and cream products of required milk fat content can be produced.

Thank You for looking at our products

- High Quality Guarantee

- Excellent Prices

- Fast Delivery

Kashkaval Cheese Unit

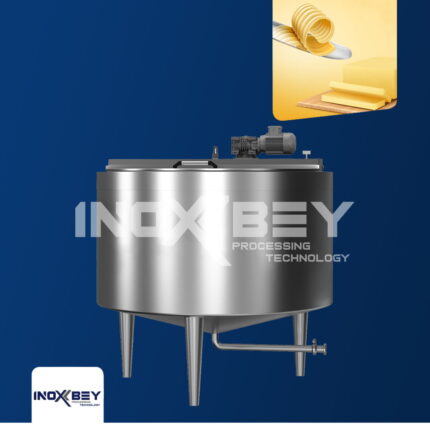

Kashkaval Cheese Unit Butter and Cream unit

Butter and Cream unit Whey Cheese Unit

Whey Cheese Unit Halloumi Cheese Unit

Halloumi Cheese Unit White Cheese Unit

White Cheese Unit Mozzarella Cheese Unit

Mozzarella Cheese Unit

Yogurt and Ayran Unit

Yogurt and Ayran Unit