WELCOME TO INOXBEY

APARTNER FOR COMPLETE SOLUTIONS

SHOP NOW Download Catalog

WHAT EVER YOU HAVE IN MIND

INNOVOTATE PRODUCTION SOLUTIONS

SHOP NOW INOXBEY CATALOG

FAST AND RELIABLE

DELIVERY

CONSUMER

PROTECTION PROGRAM

24/7 SUPPORT

BEST QUALITY

Years on the market

InoxBey of Al Hariri Group

We have been serving the food industry since 1982.

InoxBey of Al Hariri Group manufacture and export processing, filling, and packing equipment for food and beverage.

We are a leading company in manufacturing packaging and filling machines located in Sakarya / Türkiye.

We produce several brands of equipment including AL HARIRI, INOXBEY, and LIONMAK.

Contact us and come visit our factory to discuss your machinery needs.

Available now $

LIONMAK Packing Machines

Established in 1982, and it has a factory in Turkey spanning an area of 2000 m 2 and a work team of 160 employees and more than 28 agents around the world .

Our management model focuses on the client and the good development of the project in collaboration with him, since after all he is the true expert in his product, who together with our technical and commercial team develop the best packaging solution.

WHEY STORAGE TANK

WHEY PROCESS TANK

WHEY FILTERING VAT

WHEY HANGER

CURD FILTRATION DRUM

CHEESE DRY COOKING MACHINE

CHEESE PROCESSING TANK

- High Quality Guarantee

- Excellent Prices

- Fast Delivery

CHEESE TRANSFER MACHINE

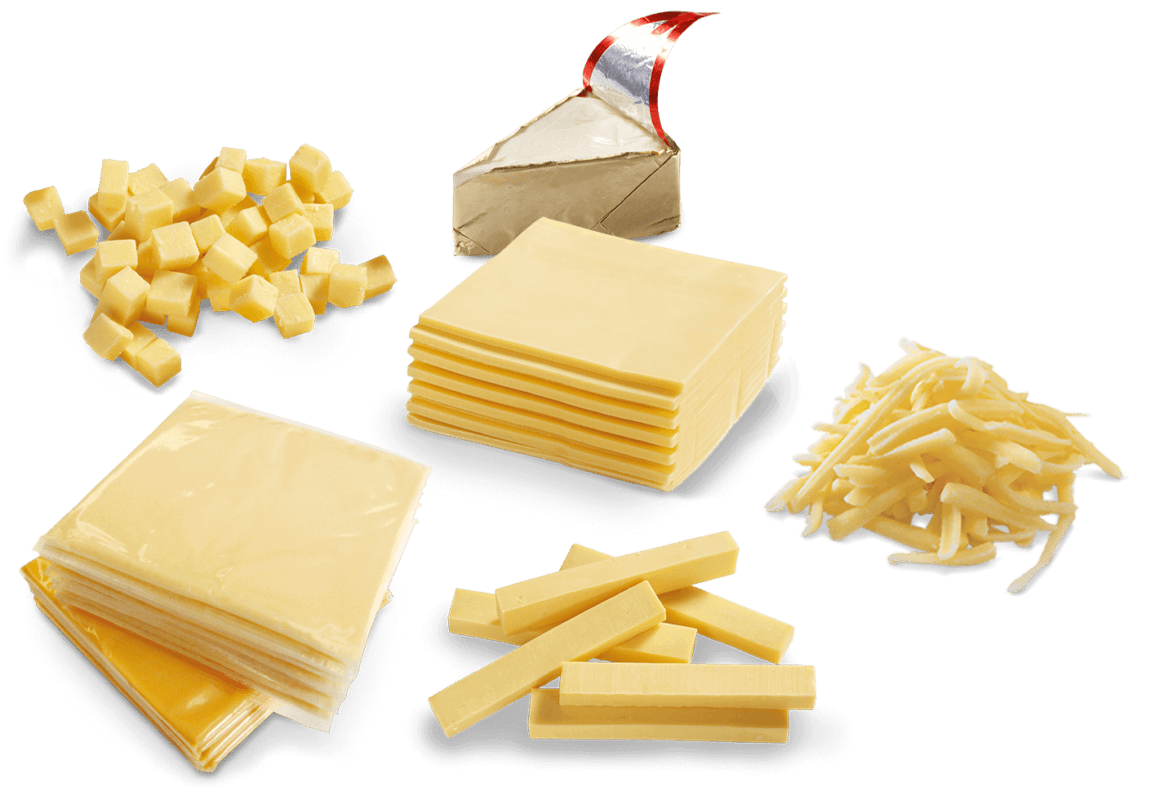

InoxBey Food Processing Technology

InoxBey is a premier, world-class solution provider in the Cheese and Dairy Products Making and Packaging equipment industry. We are a manufacturer and exporter of food production lines and filling lines

INOXBEY FACTORY IN SAKARYA

OUR LATEST NEWS

INOXBEY IN AMBALAJ 2021

-

Posted by

admin

- 0 comments

Yoghurt and Ayran manufacturing facility in the Kingdom of Saudi Arabia.

-

Posted by

admin

- 0 comments

Satisfied Customers

InoxBey Catalog

View Our Full Catalog

This is just a sample of our products and manufacturing capabilities. We also produce custom designed machinery and production lines of all kinds. Contact us by WhatsApp or Email to discuss your project needs.

Kashkaval Cheese Unit

Kashkaval Cheese Unit Butter and Cream unit

Butter and Cream unit Whey Cheese Unit

Whey Cheese Unit Halloumi Cheese Unit

Halloumi Cheese Unit White Cheese Unit

White Cheese Unit Mozzarella Cheese Unit

Mozzarella Cheese Unit

Yogurt and Ayran Unit

Yogurt and Ayran Unit