COMPLETE AND PREMIUM SOLUTIONS.

InoxBey has always aimed at offering the most advanced solutions on the market. Starting from the tomato processing, we have enlarged our business and we are now able to provide high technology equipment and 360° lines for the Food, Liquid Food, Beverage, and Lube oil sectors.

Kashkaval Cheese Unit

Kashkaval Cheese Unit Butter and Cream unit

Butter and Cream unit Whey Cheese Unit

Whey Cheese Unit Halloumi Cheese Unit

Halloumi Cheese Unit White Cheese Unit

White Cheese Unit Mozzarella Cheese Unit

Mozzarella Cheese Unit

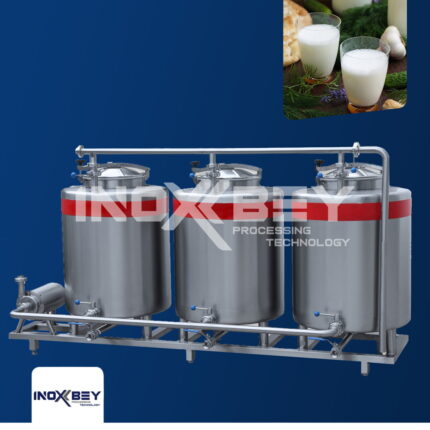

Yogurt and Ayran Unit

Yogurt and Ayran Unit