Description

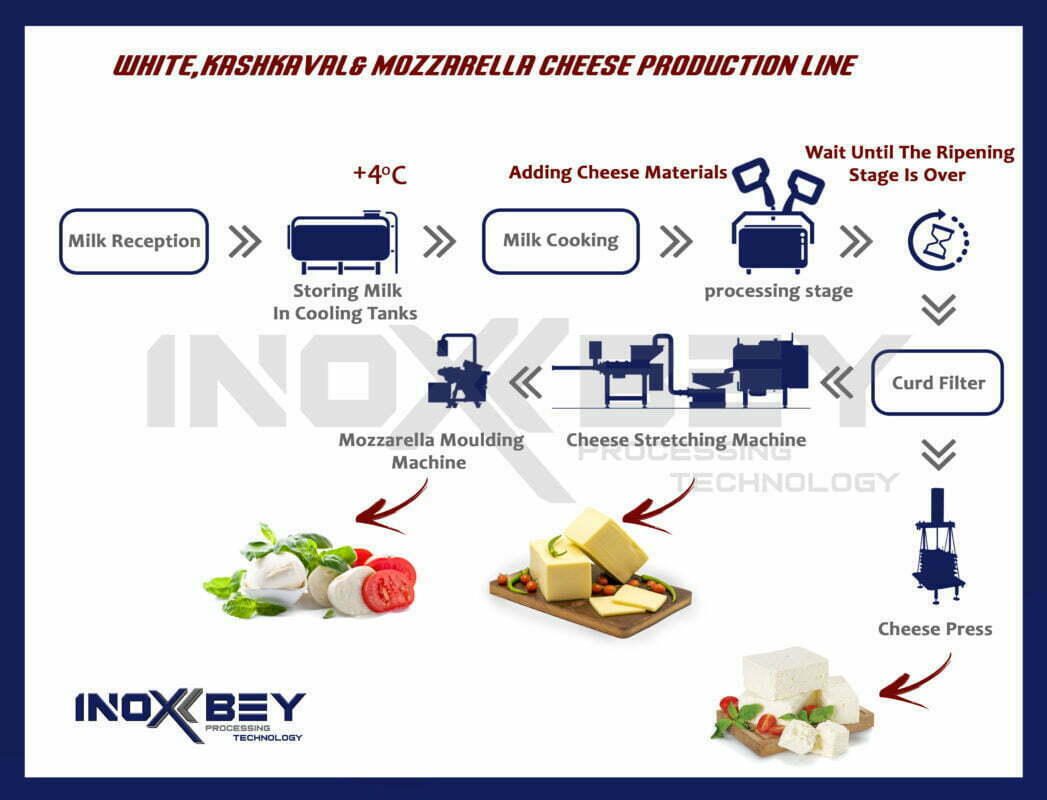

Mozzarella Kashkaval White and Fresh Cream PL (Production Line)

- MİLK POWDER BLENDER

The table blender is used to dissolve solids / powders in recirculated liquids. It has a wide range of applications, for example, preparation of pharmaceutical syrops or dissolution of pectin in glucose for marmelade production. Every model has an option with an in-line mixer for a complete dissolution of possible lumps. The typical applications are reconstitution or stabilization of milk in the production of dairy products, and dissolution of sugar for the production of syrup in the beverage industries.

The table blender is a compact unit, it consists of a centrifugal pump with a venturi system at the suction side and a hopper with a butterfly valve at the upper part to add solids / powders to the pumped liquid. In this blender, the suction and ventury system are set horizontally. If necessary, an in-line mixer can be installed after the centrifugal pump to reduce the size of possible lumps.

The venturi system and the suction of the pump create depression at the base of the hopper. When the valve of the hopper opens, the solids are drawn from the hopper and are totally dissolved when they pass through the casing of the pump.

To achieve the best possible dissolution, it is recommended to recirculate the product (batch production) till all the solid / powder product is suctioned and then, when the solid product is completely incorporated into the liquid, continue recirculating the product for a while. In some cases, the blender can be used in-line depending on the solid product to add and the required level of dissolution.

- MİLK COOLİNG TANKS

It is the first stage in the production process, where milk is stored inside it, whether fresh or industrial, at a temperature of 4 degrees Celsius, until production begins.

Cooling tanks have different types, horizontal and vertical, and the appropriate type is chosen according to the volume of production and the area of the work site.

Closed type milk coolers

The tank cooler of the closed type are issued from 2.000 lt up to 12.000 lt Such a device is economically beneficial for medium and large farms, since this type of tank has an automatic flushing system, which is indispensable when cooling large volumes of milk. Closed coolers, like open coolers, operate in automatic mode, according to a similar principle. The main difference, besides energy consumption, lies in the tank washing system. Here it is automatic. After emptying the tank, the operator presses the button, after which the electronics, according to a given program, starts the flushing system.

Principle of operation

The refrigeration unit supplies liquid freon under pressure to the evaporator. There, the refrigerant boils and turns into a gaseous state. This is an endothermic process that takes place with the absorption of a large amount of heat. The walls of the tank and the product inside are cooled. Freon gas is then pumped to the condenser. There, its temperature drops due to the fact that heat is released into the atmosphere through the radiator, and the freon returns to a liquid state again. After that, the cycle is repeated until the temperature of the raw material reaches the set value within + 2…4°C. According to the indications of the temperature controller, the unit turns off automatically. It also turns on without the participation of the operator, after the sensor gives a signal about a temperature increase of 1 degree (the temperature delta can be adjusted). For uniform distribution of cold inside the volume, there is a stirrer with a frequency of 25 rpm.

The standard sequence of cycles consists of 5 stages:

- Rinsing

- Washing with alkali

- Rinsing

- Acid washing

- Final rinse.

It is possible to customize the flushing program based on the operating conditions (for example, change the flushing time of each cycle, remove or add flushing steps, change the amount of alkali, acid, water used, etc.)

- MILK COOKING TANK

Description: Designed for pasteurization of milk, cream and other liquid products, as well as for the processes of fermentation, curd and curd processing, mixing of multicomponent recipes in the food industries. The difference in the design of the bath is the presence of a Rolbont in the heat exchange jacket, which allows for rapid cooling of the product using closed cooling systems. Equipped with motor on detachable frame, stainless steel tap with 40mm bore, overhead product nozzle and rotary washer nozzle, single-walled two-piece hood, built-in electric heaters (or steam injectors) and electronic control unit for service, regulation and automatic temperature control product and refrigerant. Made entirely from food grade stainless steel.

- MILK CENTRİFUGAL PUMP

The pump is one of the main pieces of equipment in dairy production. By means of pumps, milk, water, disinfectant and washing liquids are pumped when washing equipment. The used milk pumps differ in their design and are divided into types – gear, barrel, rotary, diaphragm, centrifugal, screw, etc. A unit of any type has its advantages, but is not without certain disadvantages.

Given that milk has a certain viscosity, milk pumps must meet the following requirements:

- supply and pumping of milk should occur evenly;

- all internal cavities must be accessible for washing;

- the design should be easy to disassemble, or suitable for CIP cleaning in assembled form;

- the device must produce sufficient pressure at the outlet

Most often, for milk and other low-viscosity products, centrifugal pumps are used. They fully meet all the specified requirements.

Advantages and disadvantages of centrifugal milk pumps

- The advantages of centrifugal pumps are:

- design simplicity and lack of a drive mechanism (the electric pump is located on the motor shaft);

- for installation there is no need for a base;

- compactness, small size and weight;

- supply uniform and simple adjustment of the pressure, by means of a valve on the pipeline;

- simple quick disassembly and assembly during flushing;

- convenient connection of pipelines;

- reliability and long service life.

- CHEESE PROCESS TANKS

Cheese Process Tanks; These are the units where the milk to be processed into cheese is fermented, the curd is formed, the curd is broken, it is heated and cooled when necessary and it is made suitable for the next stage.

Many Hard/Semi-Hard cheeses, especially Cheddar, Mozzarella, Chechil, Knitted Cheese, Edam, Gouda, Cheddar, are produced in process tanks.

After pasteurization, the milk cooled to the fermentation temperature of the relevant product is transferred to the Process Tank, where it is fermented to form curd. Formed clot; The curd in the tank can be crushed by crushing knives and mixers and heated to the desired temperature by means of heating walls when necessary.

This VAT is designed for coagulation, cutting and processing of cheese grain. The base is double cone shaped with two valves connected with 2 pipes, 4-inch each, Stainless Steel at 45-degree angle to dispense the curd. The module is also supplied with: a manhole with internal lighting, spray balls connected with a collector, a temperature sensor installed in one of the cutting-stirring tools, level sensors, heating system and a control panel corresponding to the required level of automation.

- COOLİNG ROOM

Description: Designed for storage at medium (+8…-4 °C) temperatures of pre-cooled food raw materials or finished products. Assembled from polyurethane foam panels with a heat-insulating layer 100 mm thick; facing panels on both sides has a resistant polymer coating. Equipped with a monoblock refrigeration unit , providing a medium temperature storage mode. Distinctive features of the chamber are a convenient collapsible design, a reinforced floor with a permissible static load of up to 1500 kg/sq.m and an overlay door with a special lock and a silicone seal around the perimeter.

- STEAM COOKER – CHEESE COOKİNG MACHİNE

Batch steam cooker, stretcher and melter specially designed and manufactured for cooking, kneading, melting and stretching of all types of pasta filata (mozzarella, pizza-cheese, shredded mozzarella, kashkaval, string-cheese, kasar, provolone …), analogue cheeses and food preparations.

Its compact design & robust construction make it the perfect solution for small and medium size dairies.

The machine is equipped with counter-rotating & independent two augers allowing to process fresh curd, frozen industrial curd (cagliata), vegetable curd (veg curd – caglina) and / or food ingredients and powders.

The mechanical action of the counter-rotating & independent two augers combined with the steam heating (direct and indirect) offer many advantages in the cheese production process permitting to reach high quality product and improve the yield.

The machine is prearranged for automatic C.I.P. cleaning (as standard supply).

Compact dimensions and attractive design

Easy use and operation

Great production flexibility and excellent performance for small and medium dairy plants

Batch working

Steam cooking stretching & melting machine

Direct steam injection through the steam injectors

Indirect steam heating of the cheese mass

Adjustable speed of the stretching and kneading augers

Jacketed vat, fully insulated

C.I.P. cleaning prearranged and perfectly cleanable

Independent control of the direction of rotation of each auger and independent control of the rotational speed of each auger in order to control in the best possible way the product mixing, kneading & stretching of the cheese / product mass that becomes rich of fibers, homogeneous and very stretchy

Product and ingredients inlet opening

Additional inlet opening for production inspection and/or adding ingredients

No need of prior cutting or slicing of the curd / cagliata

Adjustable work time of each batch

Temperature probe

Automatic control of the temperature

Product discharge / outlet with pneumatically operated door

Equipped with frequency converters (one for each auger) which make the operation extremely simple. Speed regulation done via push buttons located on the control panel.

- CHEESE TRANSFER MACHINE

Used to transfer cheese between equipment

After the cheese is unloaded from the cooking machine, it is rotated within the transfer machine and then transferred to the next work stage, which could be the process of forming mozzarella balls or forming ready-made cheese molds.

The machine is a linking unit between cheese production equipment, as it can be used as an alternative to pumps in transporting curds through the different stages of cheese production.

It is made entirely of food grade stainless steel and does not contain any rubber materials. Therefore, it is more stable in work and has less failure rate.

The transfer process takes place through two spirals that push the product.

- MOZZARELLA MOULDİNG MACHİNE

The ball cheese machine we produce has a single rotating head and has a production capacity of up to 100-150 kg per hour. The machine, which performs standard cutting and weighing, has molds that can be easily removed. It is made of stainless material of AISI 304L quality, and thanks to the special material that does not grow bacteria, it provides the possibility of production at the maximum hygiene level. The machine is easy to clean and maintain. The machine is equipped with a PLC control unit to control all operations with a water pump and heat exchanger. A 304 stainless steel collection basin is attached to the machine.

Working Principle of Mozzarella Forming Machine

The product coming out of the wet or dry blanching machine is loaded into the product loading chamber of the mozzarella forming machine. The spirals in the chamber push the product to the outlet openings of the forming apparatus with the pushing power of the engine and it is dropped into the cold water pool. The cooled product is collected manually.

Mozzarella Forming Machine Technical Details

- The product inlet chamber, helical and transfer pipes are coated with Teflon to prevent sticking, and the outer surfaces are sandblasted.

- It has automatic temperature control.

- Water is given to the molds with the help of the sprinkler line and the product is removed from its place.

- Electrical panel

- IP 65 protection class stainless panel

- operator panel

- PLC control

- WATER CHİLLER

It is one of the main auxiliary equipment in dairy plants

Provides cooling water to the pasteurization unit, fermentation and Process tanks.

Compact structure, smooth operation: the unit condenser, evaporator all USES efficient threaded the pipe, the host USES imported brand the fully closed compressor, a compact structure, small volume, light weight, etc advantages;

- Perfect energy control system: the temperature controller can be according to the change of load from the adjustment to stop and open unit, etc.

- Easy operation intuitive: unit adopts imported temperature controller control units, and the parameters set is simple, direct display.

- The streamlined beautiful design, the internal according to user requirements with stainless steel tank and high performance, high flow special water pump. The pump pressure can also according to customer request configuration, the design is more flexible.

- Multiple protection system, safe and reliable: except for the compressor unit interior protection modules offers super voltage, phase lack, overload and function, but also equipped with freezing, pressure control and protection device, make

the unit work correctly.

Main components

- Main Frame

- Compressor

- Condenser

- Immersed-type Evaparator

- Fan

- Liquid Valve

- Dryer – Filter

- Solenoid Valve

- Sight Window

- Expansion Valve

- Control panel

- Low/High-Pressure Switch

- Condenser Pressure Switch

- High-Pressure Manometer

- Low-Pressure Manometer

- Vibration Receiver

- Water pump

- Water Pressure Manometer

- Water Tank

11.CHEESE WEİGHİNG MACHİN

Automatic machine to mould any type “pasta filata” stretched cheese with moisture content of 38-55%.

Moulding machine with carousel disk particularly indicated for products with low and medium moisture content such as pizza-cheese, kasar, provolone, kasseri and kashkaval.

The machine portions the product in the required cylindrical, brick or rectangular shape. Afterwards, the cheese has to be manually hold into external moulds for pre-cooling and cheese blocks hardening.

The machine allows reaching high production performance while producing a wide range of cheeses of different sizes and shapes thanks to the multiple moulding tubes custom-sized available on request.

Possible products:

- Cylindrical, brick or rectangular shapes cheese blocks

- Weight range from, 250 g up to 6 kg

- Maximum possible diameter of the cheese block 110 mm.

- Possibility to produce spherical shape cheese up to 500 g through a special moulding head

Compact dimensions

Compatible with the necessities of medium size industrial productions

High production rate, flexibility and excellent proven performance

Easy use and operation

Continuous working process

Double auger moulding machine

Carousel moulding disk of 350 mm diameter

Adjustable speed of the two moulding augers as per the production and product requirements

Adjustable height of the cheese block to diversify the product weight, while using the same forming tube (fixed diameter or section) as per the production and product requirements

Uniform filling of the forming tubes and constant product weight

The number of moulding tubes depends on the product type and size

Constant cheese temperature and excellent results of the final products thanks to a heating jacket full of water that surround the outer surface of the augers area.

- TRANSPORT TROLLY

It is used to transport cheese molds after processing to storage and cooling rooms

Made entirely of 304 stainless steel

Equipped with caster wheels for easy transportation and installation

Dimensions consistent with the size of the cheese molds, with the possibility of customization

Streamlined design with no sharp corners

- CHEESE PRESSES

frame cheese presses and hoops (or forms) work together to accomplish your cheese pressing needs. Made from stainless steel and meeting or exceeding sanitary standards, you’ll love the ease-of-use, reliability and durability of a cheese pressing system from İNOXBEY

Our custom A-frame cheese presses are made of stainless steel and designed for ease of operation, efficient use of space and optimal drainage.

Pressing

- Easily press large quantities of cheese

- Reliable, even pressure with individual cylinder controls

- If one cylinder fails, the others will continue to operate

- As stacks are compressed, more hoops can be added

- Can be designed for use with rectangular or round cheese hoops

- Ideal when paired with our 20 and 40KG. Wilson-style cheese hoops

Drainage

- Angled stacks provide optimal drainage

- Stacks are secure – no additional locking or bracing needed

- Base pan collects whey and drains it to one side

Size and Build

- Can be designed in a number of different configurations from 2 row to 10 row

- Custom row configurations also available

- Vertical design uses less floor space than horizontal presses

- Durable, stainless steel construction

- Choose 3-A leveling feet or heavy-duty casters

- Meet or exceed USDA sanitary standards

- STEAM GENERATOR

It is used in all medium and high capacity production plants. It is the main artery of the factory that supplies the equipment with the necessary steam for cooking, pasteurization and sterilization operations.

PRODUCTION FEATURES

The boiler is mainly made in accordance with EN 12953 rules and material requirements. Boiler sheets and pipes to be used in production are selected by our engineers and technicians, who are experts in their fields, in accordance with their technique. In order to ensure good combustion, which is the main condition for obtaining an excellent boiler efficiency, the combustion chamber is produced in sufficient length and diameter.

In the design of the boiler, there is absolutely no objectionable practice in terms of boiler technique, such as placing excessive thermal load on the heating surfaces in order to use less material and therefore to reduce costs. The thermal load is brought to the unit heating surface (square meter) at the most appropriate rate.

Thus, the danger of facing the danger of the combustion chamber collapsing due to regional overheating due to the difficulty of heat transfer, even in the case that the material (especially the combustion chamber) gets tired quickly and even if very little calcification (scale) occurs on the water side of the combustion chamber is completely eliminated. is happening.

Smoke pipes are welded to the mirror; Thus, in case of burning natural gas / LPG, heat accumulation at the pipe ends is prevented and the strength between the mirrors is increased.

A sufficient number of manholes and handholes are left on the boiler body. Boiler doors are produced by pouring fire concrete with an insulating material placed behind it in a way that is leak-proof and to minimize heat loss. After the production, the boiler body is 100 mm after the leakage control is done by applying the hydraulic test at the trial pressure to the boiler.

NATURAL GAS BURNER AND ACCESSORIES

It is the type of burner that is produced to work in harmony with our steam boiler and does not have service and spare parts supply problems.

BOILER FIXTURES AND AUTOMATICS 1 group

Main steam valve: PN16 DN 80 BONETTİ 1 pc.

Air release valve: PN16 DN 25 BONETTİ 1 pc.

Blowdown valve (spherical): PN16 DN 50 BONETTİ 1 pc.

Blowdown shut-off valve: PN16 DN 50 BONETTİ 1 pc.

Collector blowdown valve: PN16 DN 15 BONETTİ 1 pc.

Safety valve: PN16 DN 32 UNIVERSAL 2 pcs.

Level control system: ÜLK ÜNİVERSAL 1 pc.

Level indicator : Magnetic+Reflex UNIVERSAL 2 pcs. Pressure switch: RT-116 DANFOSS 3 pcs.

Manometer : UNIVERSAL 1 pc. Alarm whistle: 1 pc.

Surface thermostat: PT 100 1 pc.

Minimum level electrodes: EA 20 2 pcs.

Vacuum breaker : UNIVERSAL 1 pc.

Cooling tower: UNIVERSAL 5 pcs.

- CHEESE GRATER MACHİNE

This high capacity cheese grating machine provides a versatile solution to grating a range of cheeses quickly and efficiently. You can even grate two different types of cheese in one operation.

The two tonne per hour industrial cheese grater will shred 1x20kg block in under 20 seconds.

The working principle of the machine: The machine contains a feeding chamber for the cheese molds that are fed manually.

All parts of the machine are made of 304 stainless steel

- 10hp motor

- Dual Shredding Chambers

- Developed for High Volume Cheese Shredding Operations

- Working well when taken out of Production

- The chamber size of 8” W x 12” H x 25” L allows processors of 40 lb (20kg) blocks to avoid size reduction operations prior to grating.

- The optional Auto-Load system includes a Quick Clean conveyor that automates the loading of the cheese shredding chamber.

- VACUUM PACKİNG MACHINE

The Double Chamber Vacuum Packaging Machine is suitable for handling food products. It is also recommended for packaging of industrial goods and laboratory instruments. It is compatible with all standard vacuum bag types and can be used in clean rooms. The characteristics of the vacuum packaging machine make it applicable to the food industry and related industries.

As standard, the cover of the vacuum chamber is made of SUS 304 stainless steel. An optional SUS 316 stainless steel lid is available. The vacuum packaging machine has a low noise level and does not cause inconvenience to the staff in the room. All two-chamber models are floor-mounted with casters for ease of movement.

The evacuation process takes place inside one of the sealed chambers above which the lid is currently located. At this time, the operator places the next batch of packages with products in the second chamber. At the end of the packaging process, the lid is moved to the second chamber and the cycle is repeated. Such scheme of work provides uniform loading of the operator and high productivity of installation.

The operator has the ability to set the vacuuming time, sealing temperature, seam cooling time. Up to 10 presets are stored in memory for different product combinations and bag types. A feature of the model is the possibility of filling the bags with an inert gas (N2, CO2).

Specifications

- Power supply: 220 / 380 V

- Power consumption: 5KW

- Weld length: 750 mm, cover – SUS 304

- Weld seam width: 10 mm

- Weight: 530 – 630 kg

- INCUBATION ROOM

DAIRY INCUBATOR (2 to 90°C)

The dairy incubators from İNOXBEY are well insulated, temperature controlled equipments that use strategically placed heating elements for forced air circulation, ensuring adequate and optimum incubation conditions for dairy products. They provide a highly controlled environment with precise temperature and humidity control and optimum O2 and CO2 concentrations to ensure reliable test results and repeatability of test conditions.

These equipments are available as pre-fabricated walk-in or reach-in incubators that use advanced technologies and an efficient design for highly reliable, economical and efficient operation. They are available in a wide variety of sizes and configurations and can be completely customized according to specific requirements.

- Environment friendly CFC free cooling

- Double walled units with powder coated mild steel exteriors and stainless steel interiors

- Highly resistant, non-corrosive surfaces

- Good grade silicon gasket fitted on the chamber and magnetic gasket fitted on outer metal door ensures zero leakage

- PID microprocessor based controllers

- Clear LED/LCD display

- Mechanical self-contained temperature limiter and an electronic safety warning device

- Equipped with NABL, CE and ISO certifications

- Calibration And Protocol Documentation

- Energy Efficient

- Versatile usage

- Ergonomic Design

- Designed for safe, reliable and long-lasting operation

- RS 232/485 interface for connecting to pc, printer etc.

- Equipped with a mechanical self-contained temperature limiter and an electronic safety warning device to prevent the working temperature from exceeding beyond the set limits.

Material Of Construction: Castor wheel mounted cabinet is double walled with inner chamber of Stainless steel sheet of grade SS 304. Outer wall is constructed out of heavy gauge PCRC steel sheet duly degreased and pretreated with primers , duly painted with attractive stove enamel or powder coated .

Temperature Range: 2°C to 90°C

Temperature Control: The equipment uses microprocessor based controllers for precise control of temperature, CO2 concentration and other operating parameters. The temperature sensors and independent high and low limit thermostats ensure greater temperature homogeneity and precise temperature control. The incubators are also provided with an integrated LED/LCD display for displaying the set point and actual working parameters.

- CREAM PROCESSİNG TABLE

It is used to make fresh cream manually. Made entirely of 304 stainless steel. It can operate on steam, natural gas or electric current. All three options can be available on the same machine

Equipped with a pressure gauge and another for measuring temperature. It can be in the form of a single basin along the entire length, or it can be made in the form of multiple trays for ease of use and provides a traditional method for making Arabic cream, which preserves the original taste of cream in Arabic sweets.

It can be available in sizes suitable for small factories and shops

Detachable and assembling tables can also be provided for ease of transportation and use

An automatic scraper can be installed for ease of work, if requested

- CIP SYSTEM

CIP (Cleaning In Place) CIP-washing is a station consisting of containers of various applications and types, designed for product washing, washing and disinfection of non-separable, hard-to-reach places, such as pipes and closed containers, which manual washing is impossible due to their design features.

All CIP-washes are arranged according to the same principle and have a common scheme of operation. Rinsing occurs by pumping special cleaning solutions through all the equipment, then rinsing with a disinfectant solution, clean water or steam treatment, after which the waste liquids are drained into the sewer. Each solution has its own container and preparation system. During the washing process, the temperature and concentration of solutions, as well as various other parameters of the installation, are controlled.

A properly built system allows you to produce high-quality and safe products, significantly reducing the cost of washing food equipment. Depending on the equipment level of the CIP-wash, washing of technological lines is possible in manual, semi-automatic and automatic modes.

For the convenience of tying, installation, maintenance and connection to highways, as a rule, the CIP washing station is installed on a common frame with a lifting element (ladder).

The list of the main elements of the CIP-wash (depends on the configuration, mode of operation and customer requirements):

- Alkaline tank

- Acid solution tank

- Disinfectant solution tank

- Circulation tank

- Clean water tank

- heat exchanger

- Dispensers (automatic cleaning solution concentration system)

- Pumps

- Valves

- Level, temperature and pressure sensors.

- Remote Control

Feature

- Safety Improvement

- Reduction of manual cleaning process.

- No equipment dismantling / vessel entry.

- Chemical handling reduction.

Enhanced Hygiene

- Reproducible, repeatable and controllable results.

- Automatic cycles ensure every item is cleaned every time.

- Human errors eliminated.

Lower Operating Cost

- Increased productivity through reduction of down time.

- Reduced expenditure of cleaning time and personnel.

- Cost savings of energy, chemicals, water used and effluent generated.

Function

This system can be built with a variety of configuration options, such as tank size, number of tanks, heating type, valve type and chemical dosing. Common components include one or more tanks, a pump, flow meter, heat exchanger, temperature transmitter, conductivity meter, and associated valves and piping. If additional hard-piping cannot be installed in a facility, or you simply demand greater cleaning flexibility, mobile CIP system or return pump cart can provide the solution.

Application

The CIP systems supplies cleaning circuits with the necessary flow velocity, temperature, and chemical concentration (alkali, acid and sanitizer) for the correct amount of time through automated control. CIP systems are widely used in dairy, beverage and juice industries.

- COOLİNG TOWER

Cooling towers are one of the types of heat exchange equipment that is used in technological processes at industrial enterprises. Most often, water is used as the working fluid. Cooling of the circulating water is necessary to remove heat from process equipment. The basic principle of operation is to cool the volume of liquid with a directed flow of outside air, the temperature of which is much lower than the temperature of the cooled liquid. Cooling towers are divided into three types depending on the way the coolant comes into contact with the outside air: open, closed and hybrid. Below you can find out how each of them works.

open cooling towers

In open cooling towers, there is direct contact between circulating water and outside air. Water with a higher temperature is supplied to the spray nozzles. As a result of contact of air with smaller fractions of water, a cooling process occurs. Most often, open-type wet fan cooling towers are used in large industrial plants, in local production and technological processes. Choose your own cooling tower

closed cooling towers

In closed cooling towers, there is no contact of air with the cooled liquid. Thanks to this interaction, the ingress of various debris and contaminants into the circuit is excluded. Unlike open cooling towers, both water and glycol solutions, emulsions and other liquid media can act as a working medium.

- AIR COMPRESSOR

The air compressor is a major component in factories that operate automatically, as it supplies the equipment with the air needed to operate the control valves and pistons of the packing machines.

It is always recommended to use compressors with a desiccant to obtain dry and fresh air free of moisture, which can affect the safety of the equipment

The compressor capacity is chosen according to the size of the factory and the number of equipment that needs compressed air in its work

Kashkaval Cheese Unit

Kashkaval Cheese Unit Butter and Cream unit

Butter and Cream unit Whey Cheese Unit

Whey Cheese Unit Halloumi Cheese Unit

Halloumi Cheese Unit White Cheese Unit

White Cheese Unit Mozzarella Cheese Unit

Mozzarella Cheese Unit

Yogurt and Ayran Unit

Yogurt and Ayran Unit