Production in this line is largely based on powdered milk, as there are no livestock farms in some countries.

It operates with a daily production capacity of 5 tons of milk distributed to all products according to the size of the order.

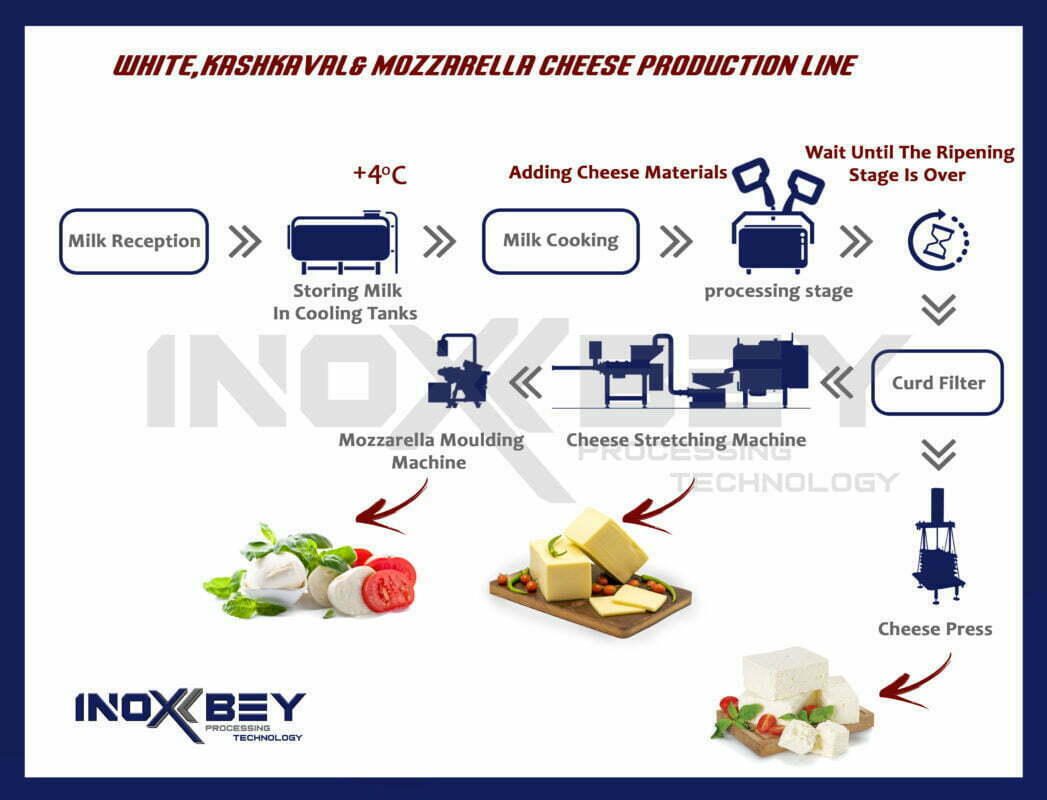

The production stages are shown according to the following diagram.

AIR COMPRESSOR

The air compressor is a major component in factories that operate automatically, as it supplies the equipment with the air needed to operate the control valves and pistons of the packing machines.

COOLİNG TOWER

Cooling towers are one of the types of heat exchange equipment that is used in technological processes at industrial enterprises. Most often, water is used as the working fluid. Cooling of the circulating water is necessary to remove heat from process equipment. The basic principle of operation is to cool the volume of liquid with a directed flow of outside air, the temperature of which is much lower than the temperature of the cooled liquid. Cooling towers are divided into three types depending on the way the coolant comes into contact with the outside air: open, closed and hybrid. Below you can find out how each of them works.

CIP SYSTEM

CIP (Cleaning In Place) CIP-washing is a station consisting of containers of various applications and types, designed for product washing, washing and disinfection of non-separable, hard-to-reach places, such as pipes and closed containers, which manual washing is impossible due to their design features.

CREAM PROCESSİNG TABLE

It is used to make fresh cream manually. Made entirely of 304 stainless steel. It can operate on steam, natural gas or electric current. All three options can be available on the same machine

INCUBATION ROOM

DAIRY INCUBATOR (2 to 90°C)

The dairy incubators from İNOXBEY are well insulated, temperature controlled equipments that use strategically placed heating elements for forced air circulation, ensuring adequate and optimum incubation conditions for dairy products. They provide a highly controlled environment with precise temperature and humidity control and optimum O2 and CO2 concentrations to ensure reliable test results and repeatability of test conditions.

VACUUM PACKİNG MACHINE

The Double Chamber Vacuum Packaging Machine is suitable for handling food products. It is also recommended for packaging of industrial goods and laboratory instruments. It is compatible with all standard vacuum bag types and can be used in clean rooms. The characteristics of the vacuum packaging machine make it applicable to the food industry and related industries.

CHEESE GRATER MACHİNE

This high capacity cheese grating machine provides a versatile solution to grating a range of cheeses quickly and efficiently. You can even grate two different types of cheese in one operation.

The two tonne per hour industrial cheese grater will shred 1x20kg block in under 20 seconds.

The working principle of the machine: The machine contains a feeding chamber for the cheese molds that are fed manually.

STEAM GENERATOR

It is used in all medium and high capacity production plants. It is the main artery of the factory that supplies the equipment with the necessary steam for cooking, pasteurization and sterilization operations.

CHEESE PRESSES

frame cheese presses and hoops (or forms) work together to accomplish your cheese pressing needs. Made from stainless steel and meeting or exceeding sanitary standards, you’ll love the ease-of-use, reliability and durability of a cheese pressing system from İNOXBEY

Our custom A-frame cheese presses are made of stainless steel and designed for ease of operation, efficient use of space and optimal drainage.

TRANSPORT TROLLY

It is used to transport cheese molds after processing to storage and cooling rooms

Made entirely of 304 stainless steel

Equipped with caster wheels for easy transportation and installation

Dimensions consistent with the size of the cheese molds, with the possibility of customization

Streamlined design with no sharp corners

CHEESE WEİGHİNG MACHİNE

Automatic machine to mould any type “pasta filata” stretched cheese with moisture content of 38-55%.

Moulding machine with carousel disk particularly indicated for products with low and medium moisture content such as pizza-cheese, kasar, provolone, kasseri and kashkaval.

The machine portions the product in the required cylindrical, brick or rectangular shape. Afterwards, the cheese has to be manually hold into external moulds for pre-cooling and cheese blocks hardening.

WATER CHİLLER

It is one of the main auxiliary equipment in dairy plants

Provides cooling water to the pasteurization unit, fermentation and Process tanks.

MOZZARELLA MOULDİNG MACHİNE

The ball cheese machine we produce has a single rotating head and has a production capacity of up to 100-150 kg per hour. The machine, which performs standard cutting and weighing, has molds that can be easily removed. It is made of stainless material of AISI 304L quality, and thanks to the special material that does not grow bacteria, it provides the possibility of production at the maximum hygiene level. The machine is easy to clean and maintain. The machine is equipped with a PLC control unit to control all operations with a water pump and heat exchanger. A 304 stainless steel collection basin is attached to the machine.

CHEESE TRANSFER MACHINE

Used to transfer cheese between equipment

After the cheese is unloaded from the cooking machine, it is rotated within the transfer machine and then transferred to the next work stage, which could be the process of forming mozzarella balls or forming ready-made cheese molds.

STEAM COOKER – CHEESE COOKİNG MACHİNE

Batch steam cooker, stretcher and melter specially designed and manufactured for cooking, kneading, melting and stretching of all types of pasta filata (mozzarella, pizza-cheese, shredded mozzarella, kashkaval, string-cheese, kasar, provolone …), analogue cheeses and food preparations.

COOLİNG ROOM

Description: Designed for storage at medium (+8…-4 °C) temperatures of pre-cooled food raw materials or finished products. Assembled from polyurethane foam panels with a heat-insulating layer 100 mm thick; facing panels on both sides has a resistant polymer coating.

CHEESE PROCESS TANKS

Cheese Process Tanks; These are the units where the milk to be processed into cheese is fermented, the curd is formed, the curd is broken, it is heated and cooled when necessary and it is made suitable for the next stage.

Many Hard/Semi-Hard cheeses, especially Cheddar, Mozzarella, Chechil, Knitted Cheese, Edam, Gouda, Cheddar, are produced in process tanks.

MILK CENTRİFUGAL PUMP

The pump is one of the main pieces of equipment in dairy production. By means of pumps, milk, water, disinfectant and washing liquids are pumped when washing equipment. The used milk pumps differ in their design and are divided into types – gear, barrel, rotary, diaphragm, centrifugal, screw, etc. A unit of any type has its advantages, but is not without certain disadvantages.

MILK COOKING TANK

Description: Designed for pasteurization of milk, cream and other liquid products, as well as for the processes of fermentation, curd and curd processing, mixing of multicomponent recipes in the food industries. The difference in the design of the bath is the presence of a Rolbont in the heat exchange jacket, which allows for rapid cooling of the product using closed cooling systems.

MİLK COOLİNG TANKS

It is the first stage in the production process, where milk is stored inside it, whether fresh or industrial, at a temperature of 4 degrees Celsius, until production begins.

Cooling tanks have different types, horizontal and vertical, and the appropriate type is chosen according to the volume of production and the area of the work site.

MİLK POWDER BLENDER

The table blender is used to dissolve solids / powders in recirculated liquids. It has a wide range of applications, for example, preparation of pharmaceutical syrops or dissolution of pectin in glucose for marmelade production. Every model has an option with an in-line mixer for a complete dissolution of possible lumps. The typical applications are reconstitution or stabilization of milk in the production of dairy products, and dissolution of sugar for the production of syrup in the beverage industries.

Kashkaval Cheese Unit

Kashkaval Cheese Unit Butter and Cream unit

Butter and Cream unit Whey Cheese Unit

Whey Cheese Unit Halloumi Cheese Unit

Halloumi Cheese Unit White Cheese Unit

White Cheese Unit Mozzarella Cheese Unit

Mozzarella Cheese Unit

Yogurt and Ayran Unit

Yogurt and Ayran Unit